What Is Asphalt Mixing Plant

Asphalt mixing plants, also called asphalt plants or hot mix plants, are equipment that can combine aggregates and bitumen to produce asphalt mix for road paving. Mineral fillers and additives may be required to add to the mixing process in some cases. The asphalt mix can be widely applied for the pavement of highways, municipal roads, parking lots, airport expressway, etc.

There are many different types of asphalt mixing plants. Different types are suitable for different projects. So what types of asphalt mixing plant are available for you to choose?

How many types of concrete batching plants are there? To learn about or to purchase concrete batch plants, figuring out the classification of them is undoubtedly the most primary and critical step. The classification methods of concrete plants nowadays are so diverse and complex that some confusion may arise in your mind from time to time. The following summary will help you tackle this problem.

How Does An Asphalt Batching Plant Work?

Asphalt batching plant is a set of equipment that produces final mixture batch by batch, and characterized by intermittent pauses between batches. Due to the accurate weighing system for dosing the aggregates, bitumen and other admixtures, the products of it are of high quality. There is a time interval between two mixing batches because of the mixer, so it's also known as the discontinuous or intermittent type.

In asphalt batching plants, the mixer with double arms and paddles means the mixing quality is undoubtedly better when compared with continuous plants because it is forced.

Asphalt mixing Plant Process Flow

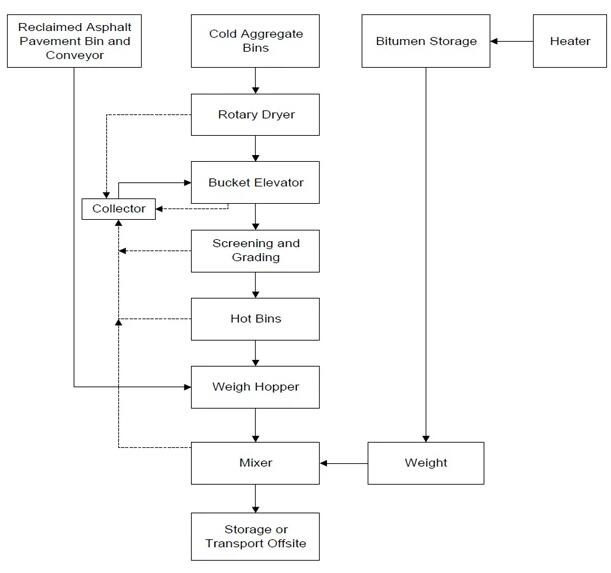

Working Process of Asphalt Batch Plants:

1.Cold aggregates feed into Drying drum

2. Burner heating the aggregates

3. After dried, the hot aggregates come out and enters the elevator, which transports them up to the Vibrating screen system

4. Vibrating screen system separate the hot aggregate to different specifications, and store in different hot aggregate hoppers

5.Precise weighing of the aggregate, filler and bitumen

6.After weighing, the hot aggregate and filler are released to the mixer, and the bitumen will be sprayed in the mixer

7.After mixed for about 18 - 20 seconds, the final mixed asphalts is discharged into the waiting truck or the special finished asphalts storage silo.

Please keep in mind that commonly the concrete must be prepared, transported, and then applied between 30-45 minutes, which is also known as preparatory setting time, concrete must not segregate in the whole course.

Advantages of Asphalt mixing Plants

Asphalt mix plants manufacture a very high-quality finished product due to the accurate measurement of each batch produced.

The intermittent production process enables them to easily switch back and forth between different mix specifications if necessary.

In batch plants, the pug mill uses arms with paddles attached to them, thus creating a forced or physical mixing of the components.

In most cases, they come with baghouse dust collectors. The dust generated during the whole process could be captured, leaving the surrround environment not polluted that much.

Mixing raw materials with stable, advanced production technology, using computer control, accurate measurement, testing means complete, stable and reliable quality, rich high strength, thus greatly improving the construction quality level building (structure).

Construction units use commercial mixing stations, the construction speed increases, reducing equipment, racks, pipes, templates and other turnover rental costs; owners of units can shorten the construction cycle, reduce investment risk.

Due to the stable and reliable quality of the commercial mixing plant, the design unit can avoid the “fat beam”, “fat column” and “heavy plate” according to the design of the mixing station”.

The mix mixing station using mineral active admixtures (slag and fly ash and admixture, etc.) can greatly improve the long-term performance of concrete waterproof, antifreeze, anti cracking and abrasion resistance, and can improve the service life of a building.

Improves the construction organization, reduces labor intensity, reduces construction management costs, technical difficulty and quality risk.

Frequently Asked Questions (FAQs)

-

How much does an asphalt plant cost?

Ranging from $100,000 to $5,000,000, the price of asphalt plant highly depends on its production capacity and the type. As a general rule, the batch mix type has more functions, and it is more complicated than a drum mix plant and hence costlier to own and operate. Drum plants are usually cheaper to own and maintain. Given the same production capacity, the prices of batch mix asphalt plants are commonly higher than their counterpart, portable asphalt plants cost substantially more than their stationary brethren. Please note that the perk of a batch plant-like best quality of mix asphalt will outrun the cheaper cost of drum plant. Tap on How Much Does An Asphalt Plant Cost to get more. -

How is the return on investment in asphalt plant?

The purchase of asphalt mixing plant actually only accounts for less than 2% of the entire investment. The procurement cost of aggregates and bitumen accounts for more than 75% of the total cost, followed by fuel, which accounts for about 12%. In other words, a set of asphalt mixing plant can bring unexpected return on investment by reducing the cost of fuel and raw materials while ensuring the output and quality of final asphalt mixture. -

Do you need a new asphalt plant or a used one?

Both have distinct advantages over the other. The advantages of a new plant are obvious: It's new, and comes with full factory support. Then, most factories will assist you in the set-up, debugging and trial production of the equipment. Plus, they are willing to help you train operators upon your demand. This is a real plus for companies new to the world of asphalt plants. Used plants can be considerably less expensive. Find one that is offered direct from the owner or his primary broker. In general, try to find out as much information as possible about a particular plant if it catches your eye.t -

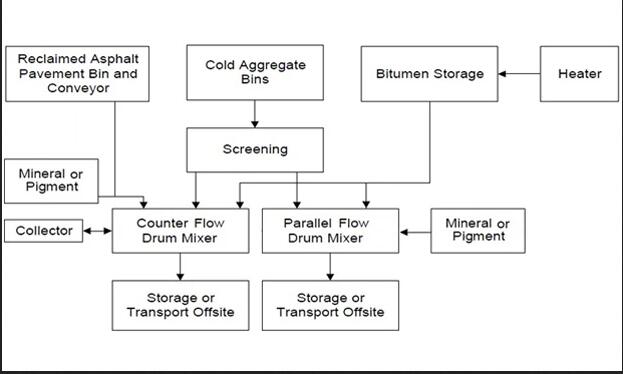

Batch mix and drum mix asphalt plant, which one to choose?

Both of them have strengths and weaknesses, just as the following table shows.

Asphalt Batch Mix PlantAsphalt Drum Mix Plant Advantages All Ingredients Are Acurately Weighed Compact Structure, Convenient for Transportation Able to Add Various Admixtures Less Land Footprint Monitor the Oil-stone Ratio in Real Time and Change Oil-stone Ratio during Operation Relatively Low Operating Cost Most Adopt Baghouse Dust Collector, Great Environmental Performance Low Investment Cost and High Cost-effectiveness High Degree of Intelligence in Control System Particularly Suitable for Projects in Rural Areas High Quality of Finished Mixture Applicable to Large-scale and High-grade Road Construction Projects Disadvantages More Land Footprint No Acurate weighing and Precise Screening Higher Initial Investment Can't Add Various Admixtures High Maintenance and Operation Cost Unable to Monitor and Accurately Change Oil-stone Ratio during the Operation Complex Structure, Not Easy to Master Quickly Simple Dust collectors and Relatively Less environmental-friendly Lower Quality of Finished Mixture -

Where to buy a higher performance-to-price ratio asphalt plant?

The answer is China. For Some reasons. As Top 5 Asphalt Plant Manufacturers In The World suggests, those shiners like Ammann, Benninghoven, Astec, own sophisticated manufacturing and management experience, as well as the rich techniques accumulated in long history, Yet due to the high human resource cost and corporation running cost, Asphalt plants manufactured by them are so costly that many buyers from developing areas need to make great efforts to afford them, or even can't burst out such ideas. China is the right place to turn to. Other than that the prices of hot mix plant products are two or three times lesser than those of European and American peers, the gap in quality is being narrowed. If you intend to purchase a cost-effective pavement material production plant, Tips for buying asphalt plants from China is highly recommended to you.