What Is Mobile Concrete Batching Plant

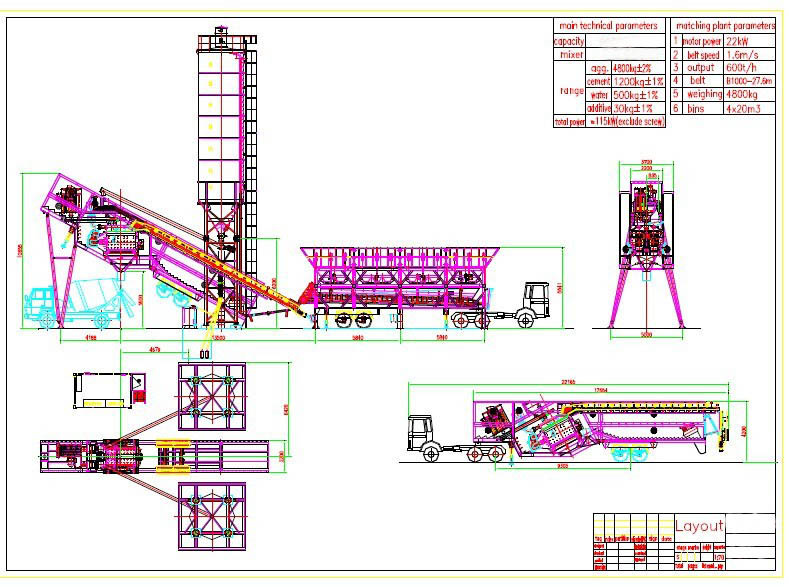

The mobile concrete batching plant is a concrete mixing equipment that integrates the material storage, weighing, conveying, mixing, discharging and automatic control systems of the traditional stable concrete batching plant into a single trailer unit; it is as same as the stable automatic concrete batching plant.

Mobile Batching plant capacity ranges from 25m³/h to 90m³/h,Mobile concrete batching plant allow for the rapid production of concrete in construction projects. They are particularly used in remote and challenging construction sites, road construction, bridge building, housing projects, and large construction sites. With mobile plants, it is possible to produce different mixtures of concrete according to the needs of the project.

Specifications

| Type | YHZS25 | YHZS35 | YHZS60 | YHZS75 | |

|---|---|---|---|---|---|

| Theoretical production capacity(m³/h) | 25 | 35 | 60 | 75 | |

| Concrete mixer | Type | JS500 | JS750 | JS1000 | JS1500 |

| Power(KW) | 24.75 | 38.6 | 51 | 65.5 | |

| Discharging capacity(L) | 500 | 750 | 1000 | 1500 | |

| Aggregate size(Pebble/Macadam)(mm) | 80/60 | 80/60 | 80/60 | 80/60 | |

| Aggregate Bin volume(m³) | 3.2 | 7.3 | 8.3 | 12 | |

| Weighing Accuracy | Aggregate (KG) | ±2% | ±2% | ±2% | ±2% |

| Cement(KG) | ±1% | ±1% | ±1% | ±1% | |

| Fly ash(KG) | ±1% | ±1% | |||

| Water (KG) | ±1% | ±1% | ±1% | ±1% | |

| Additive(KG) | ±1% | ±1% | ±1% | ±1% | |

| Total power(KW) | 50Kw | 64Kw | 85Kw | 110KW | |

| Discharging height(M) | 2.8 m | 2.8 m | 2.8 m | 3.8m | |

| Gross weight(T) | 12 | 16 | 20 | 50 | |

How Does A Mobile Concrete Batching Plant Work

A wheel loader will feed the 4 different hoppers for different sizes aggregates, and then the aggregates and sand will be weighed by the load cells, and the cement comes from the cement silo by the screw conveyor, water is supplied by the water pump will be weighed as well by different load cells, then all of these material will be fed into the mixer for mixing.

After mixing, the concrete will be discharged into the concrete mixer truck. All of the weighing, mixing and discharging process are controlled by the software automatically.

Mobile Concrete Batching Plant Process Flow

Mobile Batching Plant Operation Procedure

1. Load the aggregates like gravel and sand into individual storage bins, and after being weighed individually, they will be dispatched to the feeding belt conveyor, which then convey them to the weighing hopper on the top of the concrete mixer.

2. Under the control of the control system, the cement is transported to the weighing hopper by the screw conveyor; the water and additives are also transferred to their respective weighing hoppers.

3. Open the pneumatic door of the weighing hoppers; open the pneumatic butterfly valve of the cement weighing hopper, fly ash weighing hopper, and the water weighing hopper; Open the pneumatic ball valve of the additive weighing hopper.

4. Turn on all the weighing hopper vibrators and water inlet pressure pumps to make all materials enter the concrete mixer to blend evenly.

5. Once the setting time is over, the mixer will discharge the mix into a transit mixer or a concrete pump.

Advantages of Mobile Concrete Batching Plants

Easy transportability speeds up the transportation processes.

Their quick setup allows for time savings.

These plants require less manpower.

Producing close to the project site prevents material waste.

Mobile plants enable more environmentally friendly production.

They can be used in different projects and reduce raw material costs in the long term.