What Is concrete mixer pump

A concrete mixer pump is a machine that can both produce and deliver concrete. It combines the functions of a concrete mixer and a concrete pump.

Concrete pumps can move large amounts of concrete as quickly as a truck mixer can discharge it. Many pumps can move 30 to 100 cubic meters of concrete per hour.

Concrete pumps can reach up to 150 meters long, so they can deliver concrete quickly, even to difficult access routes. Ground line pumps can transport concrete at around 1m3 per minute.

Concrete mixer pumps can be a good investment for construction companies that use heavy materials like mud, gravel, and wet cemen

Types of Concrete Mixer Pump

1) Diesel Concrete Mixer Pump

| SMCMP10D Diesel Concrete Mixer Pump | SMCMP15D Diesel Concrete Mixer Pump | SMCMP25D Diesel Concrete Mixer Pump |

Capacity: 15 m3/h Diesel Engine Brand: Weifang Diesel Engine Power: 66 kw Concrete Mixer Type: Drum mixer |

Capacity: 15 m3/h Diesel Engine Brand: Weichai Diesel Engine Power: 82 kw Concrete Mixer Type: Drum mixer |

Capacity: 25 m3/h Diesel Engine Brand: Weichai Diesel Engine Power: 82 kw Concrete Mixer Type: Pan mixer |

|

|

|

| Model | SMCMP10D | SMCMP15D | SMCMP25D |

| Production Capacity (m3/h) | 10 | 15 | 25 |

| Concrete Mixer Type | Drum mixer | Drum mixer | Pan mixer |

| Feeding Capacity of Mixer (L) | 560 | 560 | 1200 |

| Discharging Capacity of Mixer (L) | 350 | 350 | 750 |

| Max. Pumping Pressure (Mpa) | 10 | 10 | 10 |

| Diesel Engine Brand | Weifang | Weichai | Weichai |

| Diesel Engine Power (kw) | 66 | 82 | 82 |

| Max. Delivery Distance (V/H) (m) | 80/300 | 80/300 | 80/300 |

| Overall Size (mm) | 5000*1500* 1800 | 5500*2300* 3150 | 3800*2200* 2100 |

| Total Weight (kg) | 4500 | 6000 | 5600 |

2) Electric Concrete Mixer Pump

| SMCMP10E Electric Concrete Mixer Pump | SMCMP15E Electric Concrete Mixer Pump | SMCMP25E Electric Concrete Mixer Pump |

Capacity: 10 m3/h Motor Brand: Rongcheng Motor Power: 37 kw Concrete Mixer Type: Drum mixer |

Capacity: 15 m3/h Motor Brand: Rongcheng Motor Power: 45 kw Concrete Mixer Type: Drum mixer |

Capacity: 25 m3/h Motor Brand: Rongcheng Motor Power: 45kw Concrete Mixer Type: Pan mixer |

|

|

|

| Model | SMCMP10E | SMCMP15E | SMCMP25E |

| Production Capacity (m3/h) | 10 | 15 | 25 |

| Concrete Mixer Type | Drum mixer | Drum mixer | Pan mixer |

| Feeding Capacity of Mixer (L) | 560 | 560 | 1200 |

| Discharging Capacity of Mixer (L) | 350 | 350 | 750 |

| Max. Pumping Pressure (Mpa) | 10 | 10 | 10 |

| Motor Brand | Rongcheng | Rongcheng | Rongcheng |

| Motor Power (kw) | 37 | 45 | 45 |

| Max. Delivery Distance (V/H) (m) | 80/300 | 80/300 | 80/300 |

| Overall Size (mm) | 5000*1500* 1800 | 4200*2300* 3150 | 3800*2200* 2100 |

| Total Weight (kg) | 4000 | 4500 | 4800 |

How Does concrete mixer pump Work

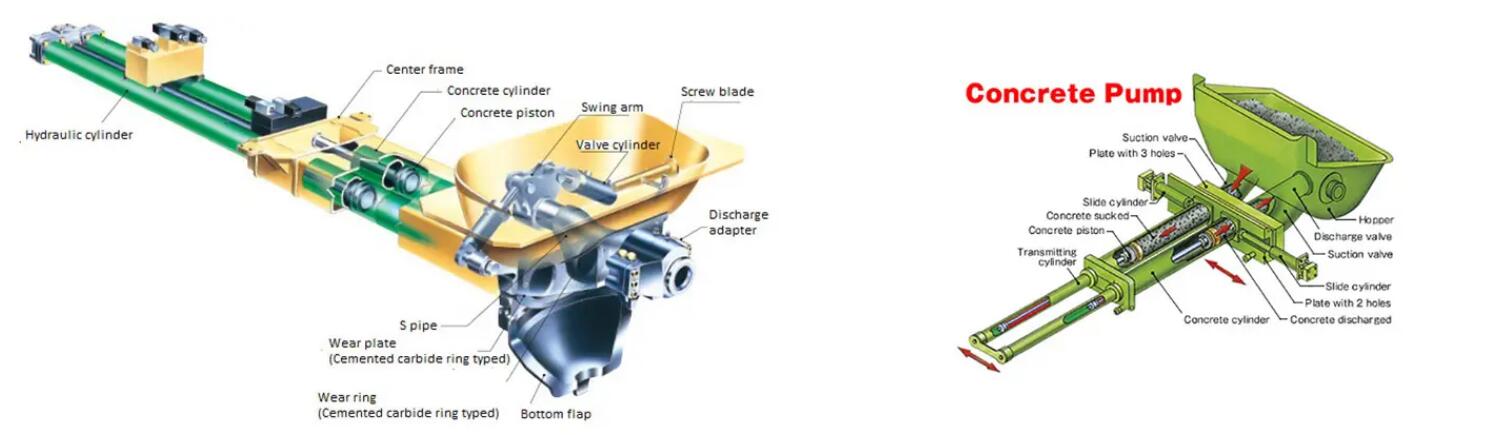

Firstly, mix the concrete in the concrete mixer and after the mixing process, and pump the concrete mixture to the construction site through the pipeline. Here will be a detailed introduction about the pumping process. Concrete piston connected with main oil cylinder piston rod does reciprocating motion when pumping the concrete mixture, under the effect of hydraulic oil of main oil cylinder.

Secondly, When the piston goes forward, the other piston will retreat. And under the effect of swing oil cylinder, S distributing valve is connected with concrete and concrete cylinder is connected with hopper. In this way, when the piston retreats, the concrete will be inhaled into the concrete cylinder; when the piston goes forward, the concrete mixture will be delivered to the S distributing valve, and be pumped to the construction site and achieve continuous delivering.

In addition, there is a reverse state. And by the reverse pump operation, connect the concrete cylinder that stays in the inhaling process with S distributing valve, and connect the concrete cylinder that stays in pushing process with hopper, and withdraw the concrete of the pipeline to the hopper. The pumping system uses S distributing valve to complete the suction and discharge of the concrete.

concrete mixer pump Process Flow

Concrete Mixer Pump Operation Procedure

Now, let's explore the step-by-step process of how a concrete mixer pump works:

1. Mixing the Concrete:

The process begins with loading the raw materials into the concrete mixer's drum. Typically, cement, sand, aggregate (such as gravel or crushed stone), and water are added in precise proportions to achieve the desired concrete mix. The mixer's drum is then rotated, allowing the mixing blades or paddles inside to thoroughly combine the materials, forming a homogeneous concrete mixture.

2. Agitating the Concrete:

After the initial mixing, the drum continues to rotate at a slower speed to keep the concrete agitated and prevent it from settling or separating during transport.

3. Transporting the Concrete:

Once the concrete is mixed and agitated to the desired consistency, the next step is to transport it to the construction site. This is where the concrete pump component comes into play:

- The concrete pump is positioned near the construction site where the concrete needs to be placed. It consists of a hopper that receives the mixed concrete from the mixer's drum.

- A concrete pump typically uses a piston or rotary pump mechanism to create hydraulic pressure. This pressure forces the concrete through a network of pipes and hoses towards the delivery point.

- The operator can control the flow rate and direction of the concrete using valves and controls on the pump. This precision allows for accurate placement of the concrete in the desired location, whether it's in a foundation trench, on a building floor, or in a high-rise construction project.

4. Pouring and Placement:

As the concrete pump delivers the mixture to the construction site, it can be directed precisely to where it is needed. The operator can control the speed and direction of the flow, ensuring that the concrete is evenly distributed and properly placed in the forms or molds.

5. Continuous Operation:

The process of mixing, agitating, and pumping concrete can be continuous, allowing for efficient and rapid construction. This is especially beneficial in projects where time is of the essence, such as concrete pouring for building foundations, roads, or bridges..

Advantages of Concrete Mixer Pumps

Concrete mixer pumps offer several advantages that contribute to their popularity in the construction industry:

1. Efficiency: They combine the functions of mixing and pumping, saving time and labor compared to traditional methods that require separate equipment.

2. Precision: The precise control of flow and direction allows for accurate placement of concrete, reducing wastage and improving construction quality.

3. Versatility: Concrete mixer pumps are versatile and adaptable to various construction scenarios and site conditions.

4. Cost Savings: Their efficiency and reduced labor requirements can lead to cost savings on construction projects.

5. Mobility: They can be easily transported to different construction sites, making them suitable for both large-scale and smaller projects.

Frequently Asked Questions (FAQs)

-

Why do some concrete pumps need to be supplied with a concrete mixer?

A concrete pump cannot dispense concrete without the use of a concrete mixer. A concrete mixer will combine all the ingredients needed to produce high-quality concrete, ensuring it is in top condition and can be pumped smoothly directly to where it is needed. Where a concrete mixer is capable of producing concrete without a concrete pump, a concrete pump cannot perform its function without a concrete mixer. Our company has concrete mixer pump for sale, welcome to contact. -

What are the horizontal and vertical pumping distances of your concrete mixture pump?

Horizontal pumping distance is 200 meters, vertical pumping distance is 50 meters. -

How many cubic meters of concrete can be pumped per hour?

A: The mixer drum can produce about 20 cubic meters of concrete per hour. The pumping system can pump about 50 cubic meters of concrete per hour.