Description of 3.5m3 self loading concrete mixer

3.5m3 self loading concrete mixer is a most popular type, with the actual capacity of 3 cubic meters per batch and 18 cubic meters per hour. The model of the 3.5m3 self loader mixer has the highest configuration, medium price, is ideal concrete production equipment. It can meet the concrete production needs of small and medium construction projects.

The function of 3.5m3 self loading concrete mixer is equal to a small mobile concrete batching plant. Owning this one self concrete mixer truck can replace the loader and a concrete mixer, reducing the investment cost.

Power Type:Diesel Engine

Wide Application Area:Self loading concrete mixer truck is widely used in house building, country road, irrigation, reservoir, mine, rural bridges, tunnel, road repair and construction, especially in remote mountainous areas or places without electricity.

Advantages Of Self Loading Concrete Mixer

- Self loading concrete mixer only needs 3 to 4 works; one worker in a cab operates the truck, and other workers complete the concrete paving. So this self loading concrete mixer not only reduces labour cost, but also improves work efficiency.

- Self loader concrete mixer can be used in rugged terrain and plateau areas. It can climb a 38-degree slope.

- It can be used for renting to others.

- This type is equipped with articulated chassis, with the advantages of flexible turning and movement.

- It is equipped with air conditioning and astern video.

- It has the most luxurious configuration, with high cost-effective.

- It is equipped famous brand YuChai engine with 85KW power.

- 80% of chassis steel is Q3458. Important parts use hard steel of 35Mnb.

- The variable angle of the logarithmic spiral ensures the mixing tank mixes concrete evenly and discharges concrete quickly. For self loading concrete mixer, discharging time is about 2 minutes, and the processing

- Capacity is about 14 m3/h.

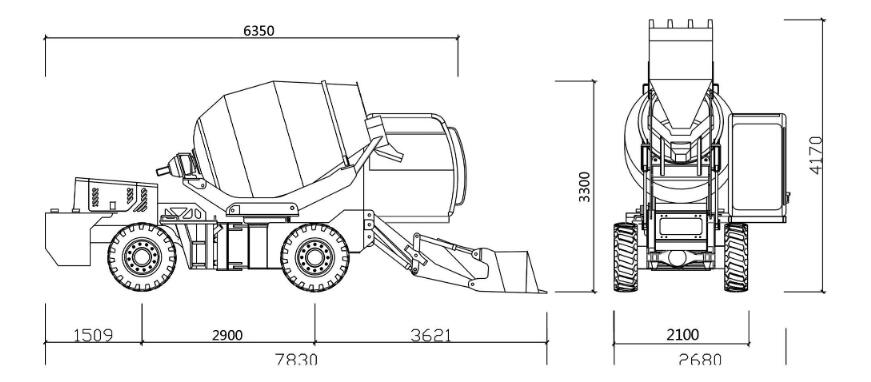

- 3.5m3 self loading concrete mixer with the length of 7830mm, width of 2680mm, and height of 3300mm, it has advantages of a small turning radius, flexible operation, and can climb the 30-degree slope.

- The cab can rotate with the mixing tank so the driver can see the discharge and concrete paving situation.

- The seats in the cab can rotate 180 degrees to achieve two-way driving, and you can return directly without turning around.

Technical Data:

| Vehicle Parameters | |

| Overall Dimensions (L × W × H) | 7830×2680×4170 |

| Wheelbase (mm) | 2900 |

| Curb Weight (kg) | 7500 |

| Drive Form | Torque converter |

| Maximum Speed (km / h) | 30 |

| Maximum Gradeability | 30° |

| Minimum Turning Radius (mm) | 5300 |

| Minimum Ground Clearance (mm) | 380 |

| Gearbox | |

| model | ZL-280 power shift transmission |

| Gearshift | 4 forward 4 back |

| Service Refill Capacities | |

| Fuel Tank: | 75 liters |

| Total Hydraulic System Capacity: | 75 liters |

| Oil: s | 16 liters |

| Diesel Engine | |

| Model: | Yuchai 4105 Turbo-charged |

| Rated Power: | 85kw |

| Optional Engine | |

| Rated Power: | |

| Convention Parameters | |

| Equipment Model: | JBC-35A |

| Parameters of Hydraulic System | |

| Reducer: | HJ80-43 |

| Dual Gear Pump: | CBGQ 2040/2080 |

| Hydraulic Motor: | BM5-160 |

| Water Supply System Parameters | |

| Tank Volume: | 620L |

| Water Supply: | Time Relay |

| Mixing and Unloading |

|

The double-cone mixing drum has double-spiral mixing screws and convex bottom. Mixing Drum Geometrical Capacity: ..................... 4740L Drum Rotation Speed: .....................18-21 rpm Concrete yield: ............... 3.5m3 / Batch The counterweight mounted on the heavy duty saddle can be hydraulically slewed at 270 ° and automatically locked by a hydraulic brake. The drum rotation is achieved by gear pump and cycloidal hydraulic motor in open circuit with a manual electric valve in the driver's cabin and in the rear of the mixer. The drum rises to horizontal position through two double-acting jacks. The unloading chute is tilted by a manually adjustable handle and can be rotated by 90 °, but can not be synchronized with the tilting operation of mixing drum. Removable chutes ensure unloading directly through the hopper. Two chute extensions are provided as standard. |