Description of 6.5m3 self loading concrete mixer

6.5 self loader mixer can mix 6 cuber meters per batch. It takes about 12 minutes from loading to discharge, so 5 batches can be completed in one hour. There are 30 cubic meters per hour. Capacity per hour=6m3/batch*5= 30m3/h. Capacity/day (8 hours one day)= 30 m3 x8h=240m3.

6.5 self loading concrete mixer for sale is a vehicle which combines concrete mixer, transit mixer and whole loader, it can feed, measure, mix and discharge automatically. Our self loading concrete mixer measurement is small, which is suitable for limited site, construction, high way road, building, farm, bridges, middle projects etc.

Power Type:Diesel Engine

Wide Application Area:Self loading concrete mixer truck is widely used in house building, country road, irrigation, reservoir, mine, rural bridges, tunnel, road repair and construction, especially in remote mountainous areas or places without electricity.

Advantages Of Self Loading Concrete Mixer

- Mobile concrete mixer feature combines self-loading,weighting,mixing and discharging,it can maximize and improve the job efficiency and reduce the production cost and time.

- The clever discharge cone is designed,to provide stronger material sealing capacity and higher filling rate,thus improving the loading capacity of the tank up to 6%.

- Loading capacity is larger for the same volume.

- The center of gravity is low for the same loading capacity.

- Swing tank easy discharge to different way.

- Tank and blades are made of high-strength wear-resistant steel,with service life increased by 30%.

- Hoppers and detachable chutes are made of multilayer high-strength wear-resistant liner plate,with service life increased by 50%.

- Overall machine features attractive appearance,smooth stream line,perfect streamlined hopper,arc-shaped rear support,and full steel catwalk,giving more attractive design to provided you a new experience.

- As the complete vehicle is equipped with four-wheel drive,it can be used for efficient and stable concrete production in harsh working conditions.

- It can be used for aggregate weighing in the process of loading,thus ensuring that concrete meets the construction requirements and weighing precision within ±3%.

- Unique continuous trace design is used,with residual rate≤0.4%.

- Large gliding angle is designed at rear cone,to ensure fast discharge at idle speed.

- Integrated control is used with one-inlet and multiple-outlet applied,convenient and fast.

Technical Data:

| Vehicle Parameters | |

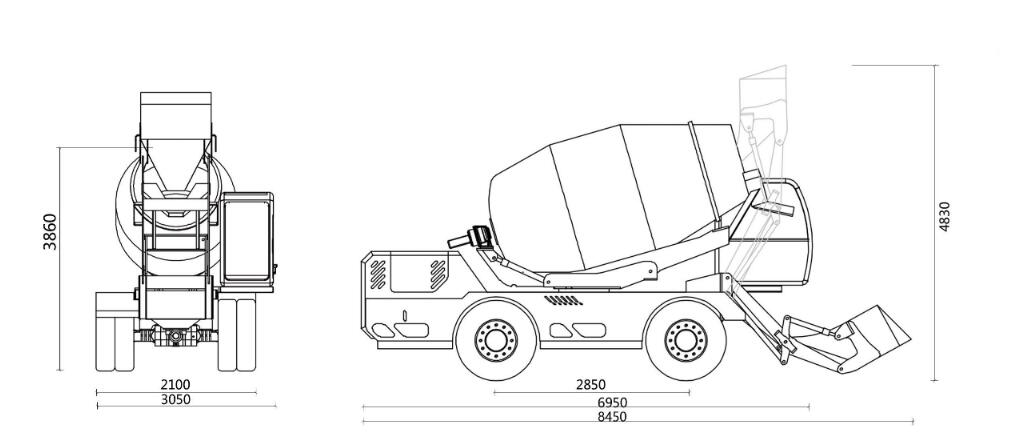

| Overall Dimensions (L × W × H) | 8450×3050×4830 |

| Wheelbase (mm) | 2850 |

| Curb Weight (kg) | 12520 |

| Drive Form | Torque converter |

| Maximum Speed (km / h) | 40 |

| Maximum Gradeability | 45° |

| Minimum Turning Radius (mm) | 4800 |

| Minimum Ground Clearance (mm) | 350 |

| Gearbox | |

| model | ZL-428 power shift transmission |

| Gearshift | 4 forward 4 back |

| Service Refill Capacities | |

| Fuel Tank: | 370 liters |

| Total Hydraulic System Capacity: | 278 liters |

| Oil: s | 16 liters |

| Diesel Engine | |

| Model: | WEICHAI DEUTZ 6105 Turbo-charged |

| Rated Power: | 92-132kw |

| Optional Engine | |

| Rated Power: | |

| Convention Parameters | |

| Equipment Model: | JBC-65 |

| Parameters of Hydraulic System | |

| Reducer: | KY07-5-j |

| Pump: | intelpump |

| Hydraulic Motor: | USA SUNNY 63 |

| Water Supply System Parameters | |

| Tank Volume: | 1465L |

| Water Supply: | Time Relay |

| Mixing and Unloading |

|

The double-cone mixing drum has double-spiral mixing screws and convex bottom. Mixing Drum Geometrical Capacity: ..................... 9000L Drum Rotation Speed: .....................16.5 rpm Concrete yield: ............... 6.5m3 / Batch The counterweight mounted on the heavy duty saddle can be hydraulically slewed at 270 ° and automatically locked by a hydraulic brake. The drum rotation is achieved by gear pump and cycloidal hydraulic motor in open circuit with a manual electric valve in the driver's cabin and in the rear of the mixer. The drum rises to horizontal position through two double-acting jacks. The unloading chute is tilted by a manually adjustable handle and can be rotated by 90 °, but can not be synchronized with the tilting operation of mixing drum. Removable chutes ensure unloading directly through the hopper. Two chute extensions are provided as standard. |